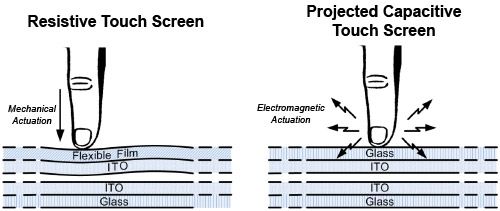

Differences between projected capacitive and resistive technologies

Inelmatic offers both projected capacitive and resistive touch displays. Each type has its advantages and disadvantages, defined by the technology used to sense the touch input.

Both are used to capture the finger position when it touches a glass placed between the display and the user, however, the method to capture the position is very different.

PROJECTED CAPACITIVE TOUCH TECHNOLOGY

Project capacitive touch (also called PCT or PCAP) is a very common touch type, found in almost every cellphone and tablet in the market.

How does it work?

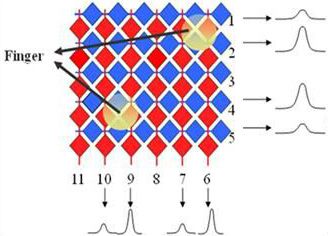

It's based on crossed conductive transparent patterns arranged in rows and columns on one or two sheets of glass (glass to glass - GG), film (film to film - FF) or a combination (glass to film - GF).

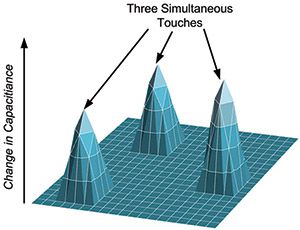

The touch controller will measure the mutual capacitance between rows and columns, creating a virtual "map" of the areas detecting the difference of capacitance caused by the finger proximity and touch.

This method of detection allows to detect more than one touch simultaneously achieving multi-touch seamlessly. Projected capacitive touch panels are known by its high sensitivity and optical performance, while having limitations on the type of material that the sensor could detect. Low density materials such as cloths, wood, plastics, etc. are non detectable, because the capacitance difference compared to the air is very small. This makes using standard stylus pens impossible, limiting the activation to the finger or special stylus pens. In the other side, droplets and pouring liquids on the touch could cause fake touch inputs, masking the real finger positions.

These disadvantages above are avoidable by adjusting the controller's firmware to each situation, however, in certain occasions, the traditional Resistive Touch technology is the only able to completely solve the Projected Capacitive Touch limitations.

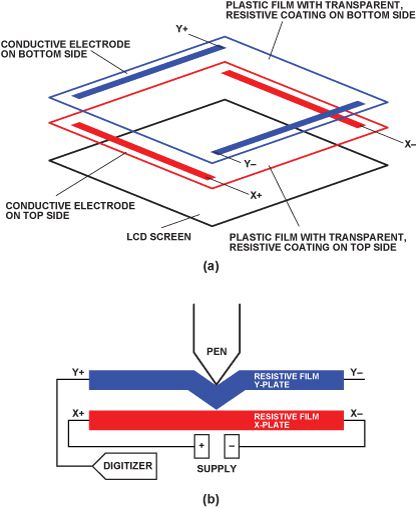

RESISTIVE TOUCH TECHNOLOGY

A resistive touch screen contains two conductive layers, separated by spacer dots. One layer is excited with a constant voltage, When an element touches the surface of the outer layer, both conductive layers come into contact. This creates current between the two layers. The touch controller measures the voltage drop in the non excited layer, being proportional to the position. This measurement is repeated swapping the layers, obtaining the touch point coordinate X-Y.

Resistive touch screens are usually cheaper, but they lose 25% of their brightness because they two ITO layers and one being plastic. An additional disadvantage is that they can be damaged by sharp elements and they need calibration over time, due the loss of linearity of the conductive layers. Although there are different technologies (5W, 8W) to compensate this loss of linearity, the endurance of a touch panel still its handicap.

Inelmatic supplies a special type of armored resistive touch often used in military applications, where the touch must detect all types of gloves and objects and sustain very EMI. This kind of touch panel also improves hardness and resistance to fire and impact.