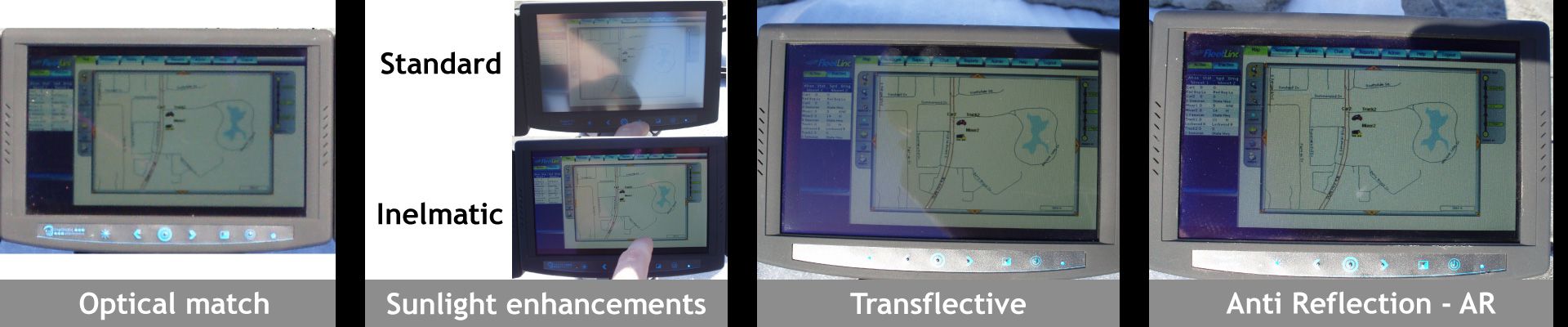

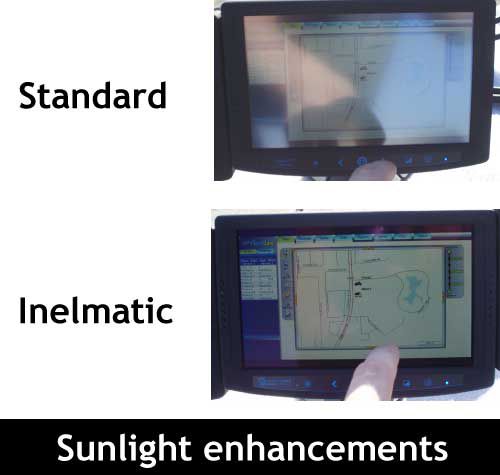

Sunlight readable enhancements

In general, LCD screens have a visibility problem when used in conditions that include high levels of ambient lighting. It is usually uncontrollable exposure to outdoor lighting, such as in automotive, industrial environments, kiosks, advertising displays etc ... The solution is to increase the brightness and contrast of the screen well above normal levels compared to use in inside. This prevents direct reflections from the screen surface.

Anti-reflection (AG) treatment is also available for 3H surface hardness. This filter reduces distracting reflections and keeps the screen clear and visible, ensuring a clear view on the screen when the light from inside or distracting sunlight from outside changes.

In the recent years, several technologies have been developed such as film lamination. Inelmatic Laboratories can enhance the visibility display by applying optical films to its front surface, thereby improving brightness and contrast by reducing surface reflections with the backlight control.

These are examples of the solutions which Inelmatic brings in the optical enhancements field:

Optical coatings

The simplest optical coatings are thin layers of metals, such as aluminium, which are deposited on glass substrates to make mirror surfaces, a process known as silvering. The metal used determines the reflection characteristics of the mirror. By controlling the thickness and density of metal coatings, it is possible to decrease the reflectivity and increase the transmission of the surface, resulting in a half-silvered mirror. These are sometimes used as "one-way mirrors".

Such coatings can reduce the reflection for ordinary glass from about 4% per surface to around 2%. Further reduction is possible by using multiple coating layers, designed such that reflections from the surfaces undergo maximum destructive interference. By using two or more layers, broadband antireflection coatings which cover the visible range (400-700 nm) with maximum reflectivity of less than 0.5% are commonly achievable.

Our R&D optical department is researching everyday new optical coating materials to reduce the reflection in the monitors and to improve the user experience in harsh conditions.

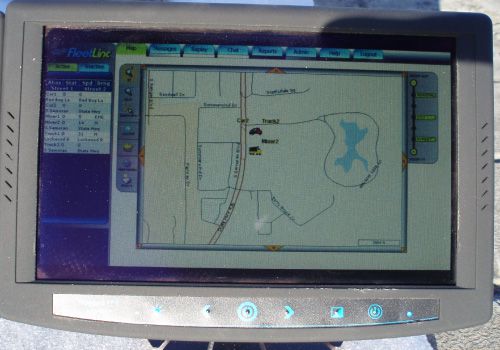

Anti Reflection (AR) films

This treatment is done laminating the front surface of the LCD panel. Can be performed either directly in-the-frame or under-the-frame. Inelmatic prefers the under-the-frame method to reduce risks of delamination.

Antireflection coatings are used to reduce reflection from surfaces. Whenever a ray of light moves from one medium to another (such as when light enters a sheet of glass after travelling through air), some portion of the light is reflected from the surface (known as the interface) between the two media.

A number of different effects are used to reduce reflection. The simplest is to use a thin layer of material at the interface, with an index of refraction between those of the two media.

Our film laminations has been designed with the best anti reflection materials with treatments developed by Inelmatic Optical laboratory.

Film laminations

Inelmatic advice the lamination under the frame to reduce lamination damaged provoked by the use. Type of film Laminations:

-

Antireflective Film (AR). Reduces surface reflections, improving brightness and contrast without making display brighter.

-

Antireflective Film and Antiglare Film (AR - AG). Allows to soften the images of the direct light source in reflection.

-

Conductive Films (EMI - RFI Reduction). They reduces the EMI emissions.

-

Privacy Films. They reduce light directed out of the viewing angle, thus preventing unwanted private information leaks.

-

Neutral Density Films. It reduces the reflected ambient light when it is greater than the emitted light, thus increasing the contrast of the screen.

-

Color Selective Films. They allow to change the color shown on the screen for special applications.

More info

Special optical requirements

If the monitor of your solution requires a special optical treatment for a installation in hard environments, please let us know, we can serve you to achieve your needs